Innovation and Precision in Action

Explore our ingenious solutions to turn your ideas into impactful realities.

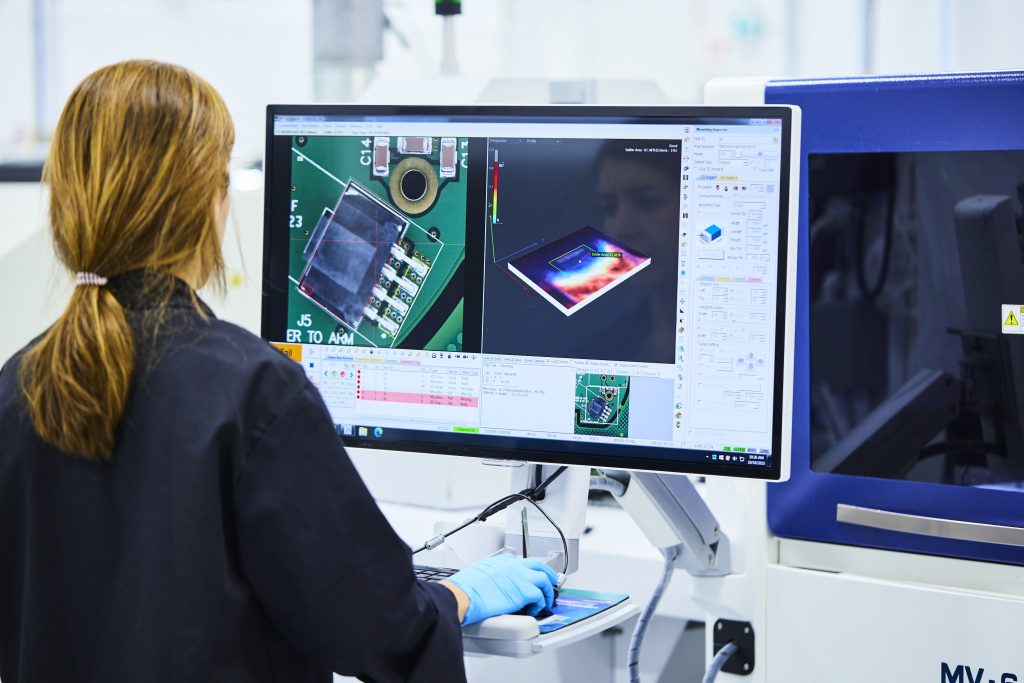

Design For Excellence (DFx)

SMT Intelligence excels in electronic assembly, product optimization, and mechanical assembly. Our DFx-centered approach aims to improve performance while adhering to the most demanding quality standards.

Based on close collaboration between our designers, engineers, and production teams, our strategy considers various parameters such as material choices, manufacturing techniques, dimensional tolerances, and assembly.

- Design for Advanced Manufacturing (DFM)

- Design for Procurement (DFP)

- Design for Assembly Optimization (DFA)

- Design for Testing (DFT)

- Design for Automation (DFC)

Industrial Design

Mechanical Design

Electrical Design

Product design and launch

From ideation to final product, our engineering team, along with our New Product Introduction (NPI) group, paves the way for limitless achievements.

Our proposition:

- Internal team and partnerships with scientific and technological experts

- Engineering department consisting of a dozen dedicated experts

- Design for Excellence (DFx) integrated at every step

- Rigorous approach and upstream validation of products

- Guarantee of high-quality products and avoidance of common delays.

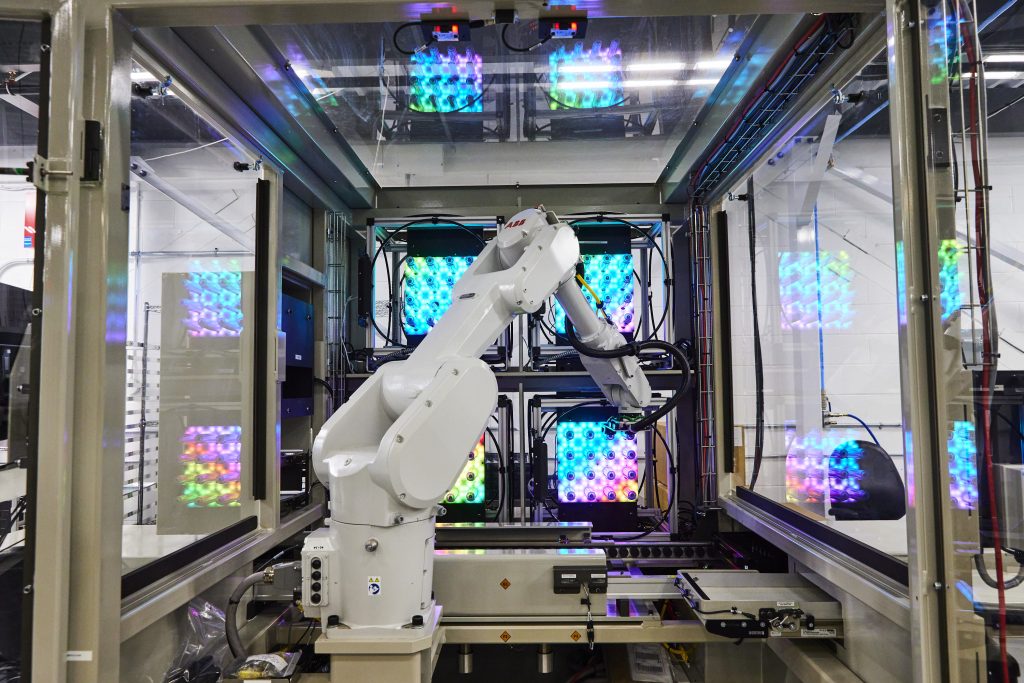

Automating a production line

Our mastery of automation is fundamental to our expertise. It enhances our production capabilities, creates a shield against human errors, and ensures the reliability of our products. It represents strategic value guaranteeing superior quality.

- Amplified production capacity

- Shield against human errors

- Reliability of products

- Guarantee of superior quality

Proactive material and supply chain management

Our approach integrates traceability solutions and detailed reporting thanks to our ERP software. This improves your production by providing a complete view of the supply chain, bringing concrete benefits to your process.

- Optimization of timelines and budgetary objectives

- Guarantee of continuous supply

- Maximization of resources

- Detailed reports on traceability

- Rigorous inspection of incoming materials and outgoing products

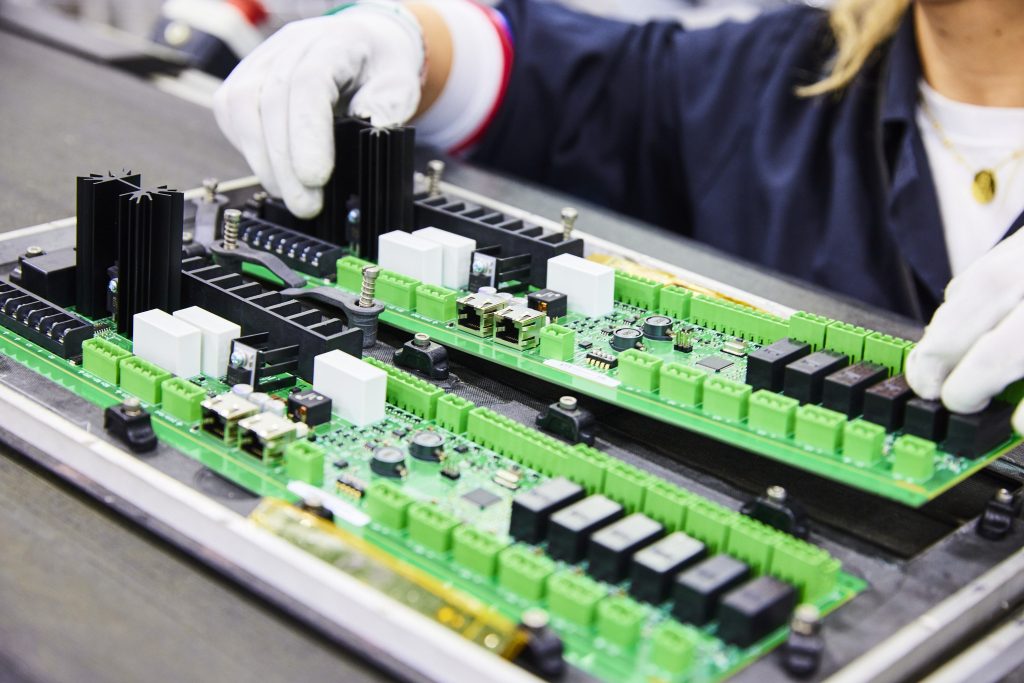

Prototyping

Prototyping is a crucial element of electronic innovation. Our service accelerates the transition from the concept idea to the functional model. With a dedicated team and meticulous processes, we support you at every step, providing a comprehensive solution for electronic manufacturing.

- Accelerated prototyping

- Dedicated team and meticulous processes

- Personalized support

- Tailored NPI strategy

- Risk reduction

- Planning for rapid market entry

- Organizational and traceability tools

- Commitment to your vision

Redesign of PCBA

We master the art of prolonging the life of your designs. Our specialization is finding replacement solutions for components no longer available in the market. By identifying equivalents or proposing alternatives, we preserve the continuity of your project during the transition to new elements.

- Expertise in life extension

- Adaptation to alternative solutions

- Maintenance of consistency

Optimization of the Bill of Materials (BOM)

- In-depth analysis of the components list

- Intelligent supply chain management

- DFP strategies

- Exploration of alternative sources

- Transparent communication

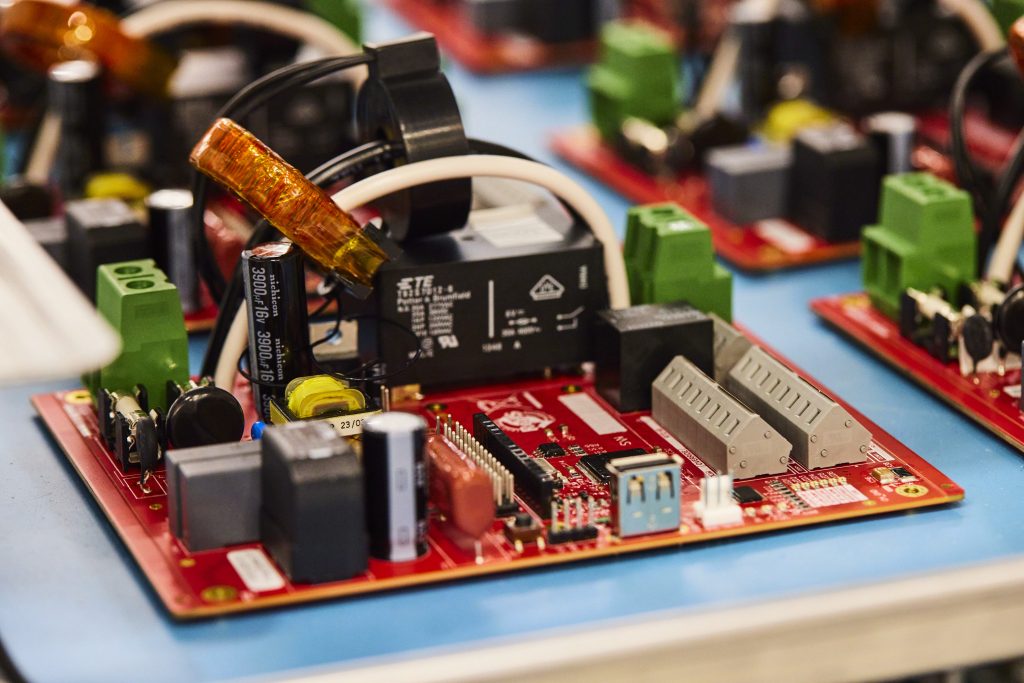

Improvement of component placement

Meticulous arrangement of components on the printed circuit board (PCBA) is essential for improving product quality. It reduces electromagnetic interference and facilitates the soldering process. Our expertise lies in our ability to efficiently orchestrate the electronic circuit, guaranteeing reliability and superior quality for our products. We integrate DFx principles to maximize these benefits.

- Meticulous arrangement

- Reduction of electromagnetic interference

- Agile soldering process

- Effective electronic circuit planning

- Integration of DFx guidelines