2 approaches

1 goal

Your Parts + Our Expertise

- Assembly and Integration

- Tests

From Design to Delivery

- Component Sourcing

- Assembly and Integration

- Tests

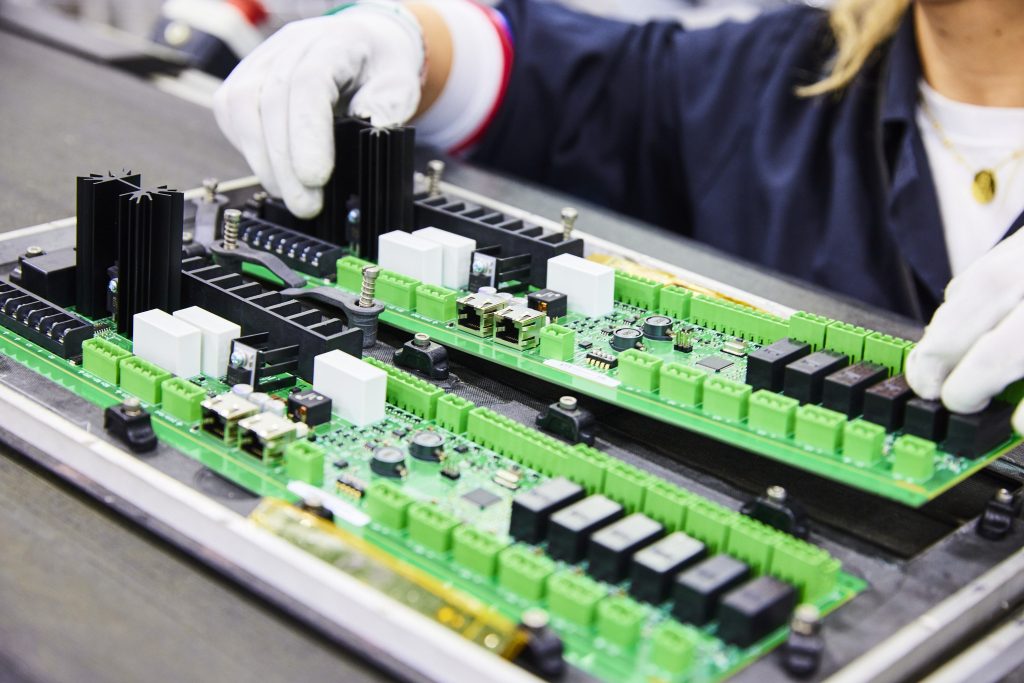

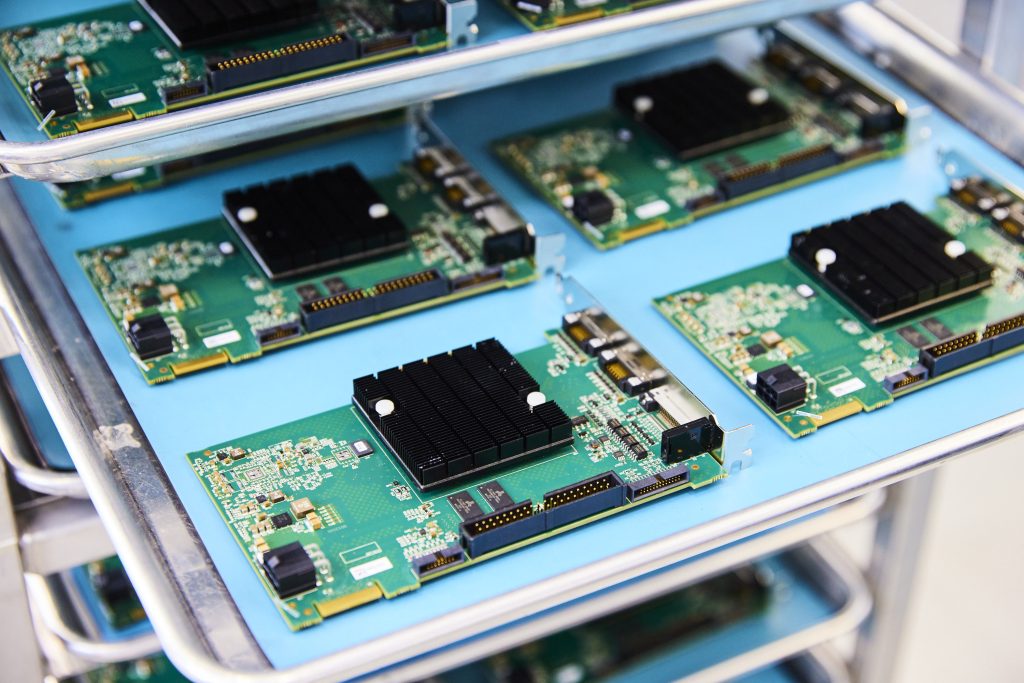

Printed circuit board assembly, PCBA

We employ the latest in automated assembly technologies to position, solder, and test each component accurately. Our custom solutions blend a variety of components: electronic, mechanical, and optical. Through active collaboration with your team, we commit to continuous improvement, providing PCBA solutions that meet your expectations.

- Unmatched Precision

- Diversity of components: Electronic, mechanical, and optical

- Active team collaboration

Encapsulation (Potting) and conformal coating

Encapsulation and conformal coating at SMT Intelligence: secrets of durability.

- Robust protection of your products

- Resistance to harsh environments

- Extended lifespan

- Protection against moisture and particles

Box Build

Understanding your requirements and the end goal of the product, we assemble, test, and manage the logistics of your finished products.

Our areas of expertise include:

- Feedback and improvement suggestions for your designs

- PCBA integration into their enclosures

- RF optimization of assembled systems

- High-volume automated mechanical assembly

- Comprehensive and varied testing plans.

High-volume automated mechanical Assembly

Innovation shines through the integration of artificial intelligence and human expertise in high-throughput mechanical assembly on our automated assembly lines. This enables us to cater to custom solutions for all production volumes, ensuring remarkable quality and performance.

- Continuous innovation

- Integration of Artificial Intelligence

- High production throughput

- Customized flexibility

Proactive supply chain management

Our approach integrates traceability solutions and detailed reporting thanks to our ERP software. This improves your production by providing a complete view of the supply chain, bringing concrete benefits to your process.

- Optimization of timelines and budgetary objectives

- Guarantee of continuous supply

- Maximization of resources

- Detailed reports on traceability

- Rigorous inspection of incoming materials and outgoing products

Inspection of incoming materials and outgoing products

We have established procedures for thorough controls, ensuring the quality of incoming materials and finished products ready for delivery.

- Inspection of incoming materials

- Controls of outgoing products

- Quality assurance at delivery

Electronic product repair and refurbishment

Our refurbishment and repair service includes expert diagnostics, integrated quality control, and transparent traceability. Give your electronic products a second life with enhanced performance and durability.

- Expert diagnosis

- Transparent Traceability

- Enhanced second life